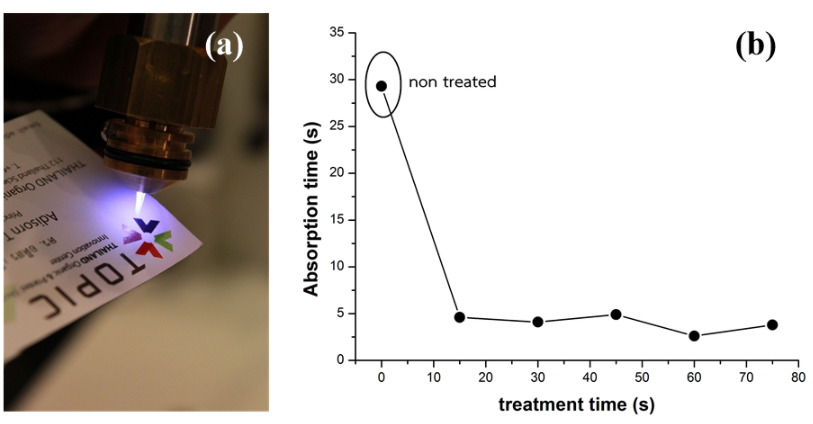

Asst.Prof.Dr. Artit Chingsungnoen and his team have developed various types of atmospheric pressure plasma jet concentrators for application for plasma surface coating or plasma surface modification by using gas emission principles through the electrode. At such areas, the electric field has to be changed with high amplitude and frequency. Gas molecules moving at high speed through the holes will collide more with each other. At the same time, electrons that are accelerated by electric fields to move back and forth will also collide with gas molecules at high frequency. Energy is transferred between electrons and gas molecules, eventually resulting in plasma disintegration. Figure 1 illustrates the use of a single-hole plasma jet with cold plasma developed by the research team (Patent No. 14444) to improve the surface of the sericin silk powder to more hydrophilic.

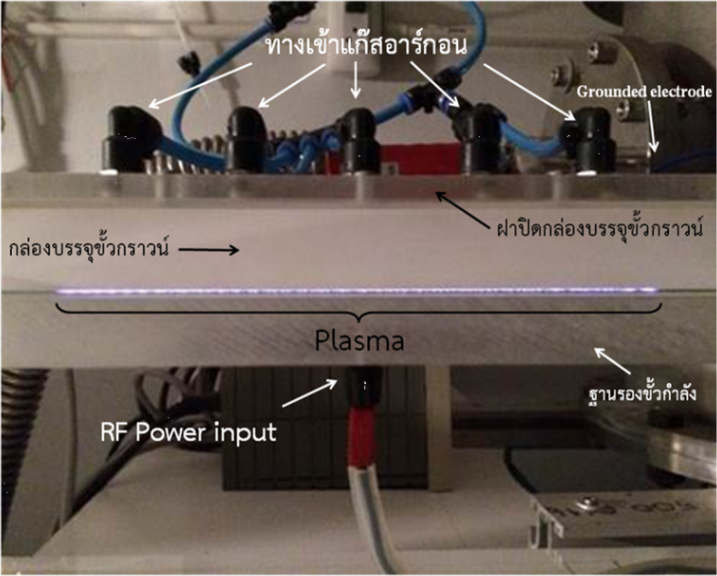

The textile industry has played a vital role in the development of the Thai economy since over the past 10 years it has been one of the country’s top export revenues. But at present, there is a quite high competition of textile products in the world market. At present, the textile industry in Thailand is still mostly low-end, focusing on labour-intensive production of inexpensive products. The researchers realized the importance of enhancing the mention competitiveness. A wide variety of unique and diverse properties are therefore designed and engineered for textile surface treatment using the atmospheric pressure plasma treatment technique from a multi-atmospheric pressure plasma jet generator which developed by the research team (Patent No. 14888 and 15314) as shown in Figure 2.

This technique has the advantage of dry surface modification, which requires no solution and no residue. The resulting plasma is cold plasma, so it can improve the fibrous surface over a wide area without altering the internal structural properties of the material. It is the development of textiles with special properties such as quick-drying properties, better water-absorbing fibres, or longer-lasting waterproof and antibacterial properties. This work has been registered by Thailand Science Research and Innovation (TSRI) under the Tech2Biz project to present a prototype technology, which has already been applied by Oasis Garment Company Limited to apply for the technology.

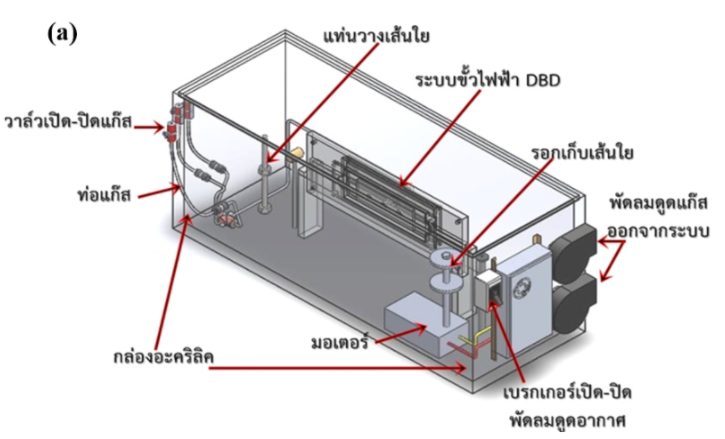

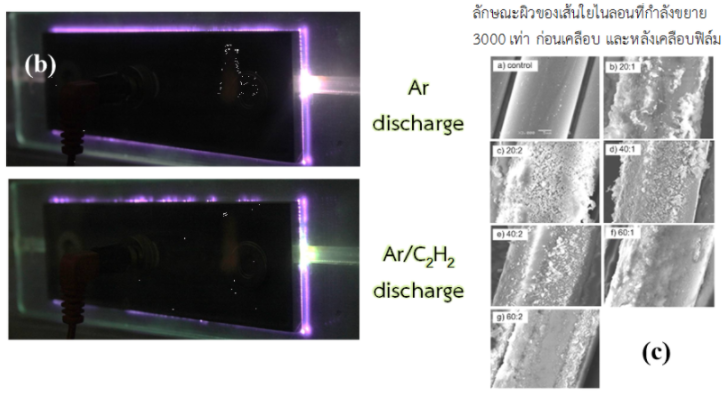

In addition to the development of atmospheric pressure plasma (APP) sources, another technique that is gaining attention is the dielectric barrier discharge, DBD. The research team developed a plasma generator device by releasing a dielectric charge at atmospheric pressure. (Patent No. 14445) to treat and coat fibre-like specimens, allowing the reactive fast radical from the plasma to bind to the fibre surface more thoroughly, as shown in figure 3.

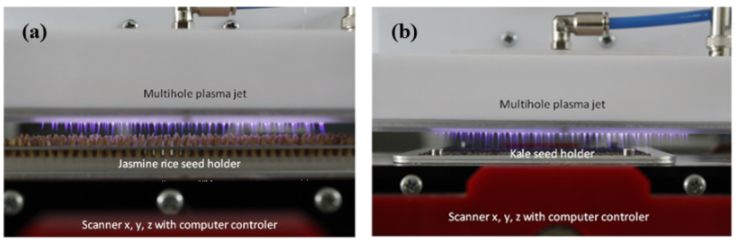

Besides, the multi-hole plasma jet generator is critical technology, the research team consisted of Asst.Prof.Dr. Artit Chingsungnoen, Asst.Prof.Dr. Phitsanu Poolcharuansin, Asst.Prof.Dr. Poramate Chunpang and Asst.Prof.Dr. Waraporn Sutthisa has filed a patent application number 1803002042, dated 11 September 2018 under the title ” Line-array atmospheric pressure plasma jet generator device” This study was able to apply plasma in the food industry and agriculture to aid in sterilization, increasing the germination and growth rates, thus attracting great interest both by agricultural scholars and plasma technology researchers. As a clean technology, no chemical residue and the need for vacuum equipment such as rotary pumps, pressure gauges and vacuum chambers, the cost of building a system can be greatly reduced. Future research aims to develop a multi-hole plasma jet generator at one atmospheric pressure and to use a seed treatment to stimulate germination and increase the rate of growth. This will benefit farmers in adding value to the products in the health consumer groups.

This plasma generator prototype was funded by the National Research Council of Thailand, the fiscal year 2017 and Electricity Generating Authority of Thailand (EGAT), the fiscal year 2019.